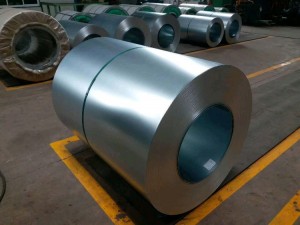

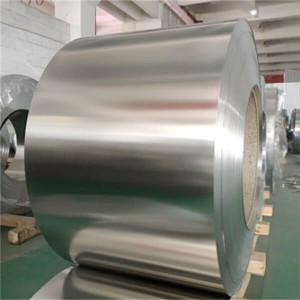

304 304L 316 316Ti 316L Stainless Steel Coil

Short Description:

Email: liu91284@gmail.com

Tel/WhatsApp: +86 18921370797

Material Grade: 304 304L 316 316Ti 316L

Surface: BA/2B/NO.1/NO.4/8K(Mirror)/HL/Brushed/Polished/Bright

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

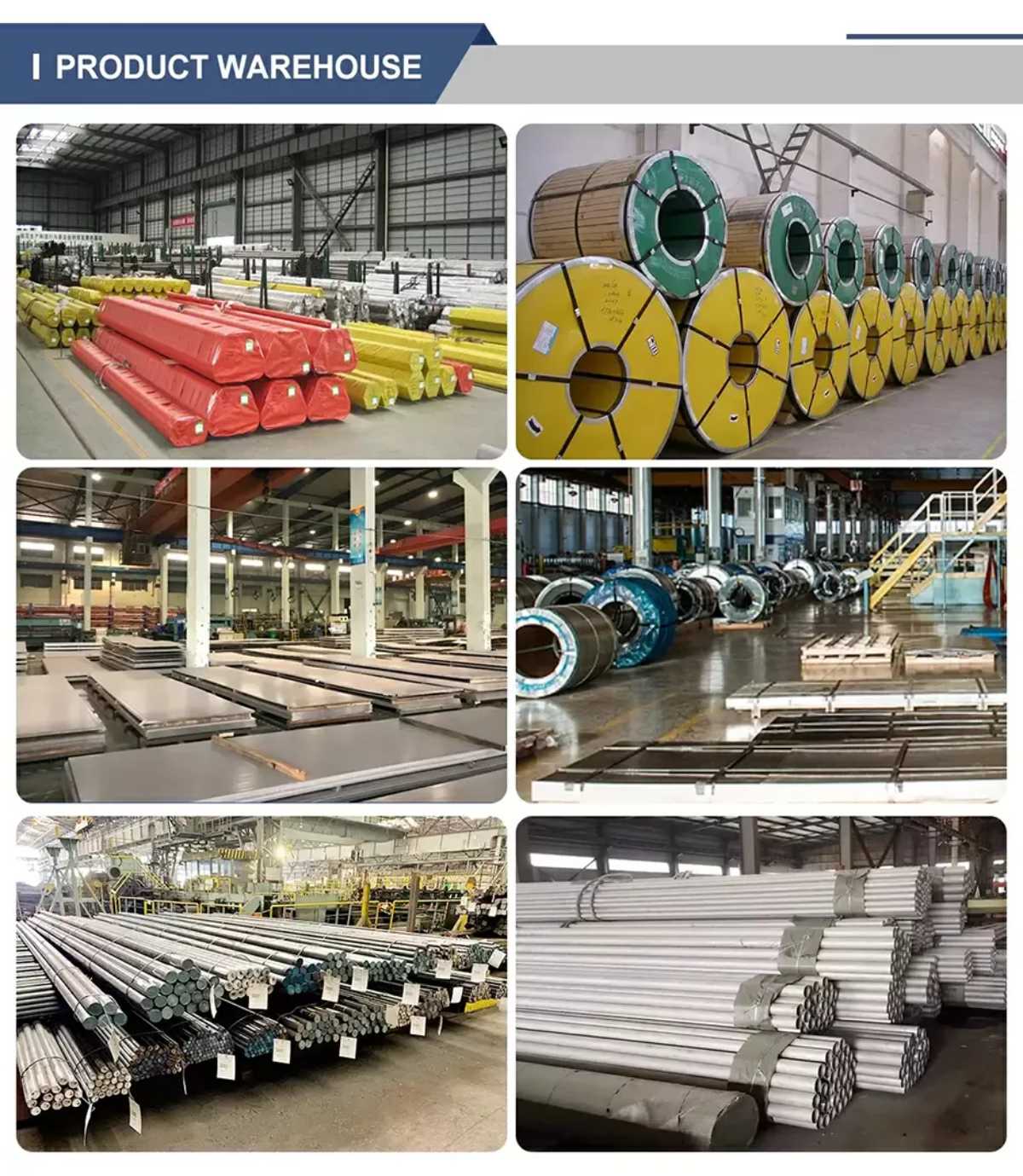

Product Details of Stainless Steel Coil

| Product Name | Stainless Steel Coil |

| Material | 304 304L 316 316Ti 316L |

| Thickness | 0.3mm -20mm |

| Width | 600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | BA/2B/NO.1/NO.4/8K(Mirror)/HL/Brushed/Polished/Bright |

| Quality test | we can offer MTC(mill test certificate) |

| Payment terms | L/C, T/T, Western Union, Cash |

| Stock or not | Have ready stocks |

| Sample | Provided Freely |

| Container Size | 20ft GP: 5898mm(Length)x2352mm(Width)x2393mm(High) 40ft GP: 12032mm(Length)x2352mm(Width)x2393mm(High) 40ft HC: 12032mm(Lengh)x2352mm(Width)x2698mm(High) |

| Delivery time | Within 7-10 Working Days |

The Difference Between 304 And 316 Stainless Steel

When selecting stainless steel that must endure corrosive environments, austenitic stainless steel is typically used. Possessing excellent mechanical properties, the high amounts of nickel and chromium in austenitic stainless steels also provide outstanding corrosion resistance. Additionally, many austenitic stainless steels are weldable and formable. Two of the more commonly used grades of austenitic stainless steel are grades 304 and 316. To help you determine which grade is right for your project, this blog will examine the difference between 304 and 316 stainless steel.

304 Stainless Steel

Grade 304 stainless steel is generally regarded as the most common austenitic stainless steel. It contains high nickel content that is typically between 8 and 10.5 percent by weight and a high amount of chromium at approximately 18 to 20 percent by weight. Other major alloying elements include manganese, silicon, and carbon. The remainder of the chemical composition is primarily iron.

The high amounts of chromium and nickel give 304 stainless steel excellent corrosion resistance. Common applications of 304 stainless steel include Appliances such as refrigerators and dishwashers Commercial food processing equipment Fasteners Piping Heat exchangers Structures in environments that would corrode standard carbon steel.

316 Stainless Steel

Similar to 304, Grade 316 stainless steel has high amounts of chromium and nickel. 316 also contains silicon, manganese, and carbon, with the majority of the composition being iron. A major difference between 304 and 316 stainless steel is the chemical composition, with 316 containing a significant amount of molybdenum; typically 2 to 3 percent by weight vs only trace amounts found in 304. The higher molybdenum content results in grade 316 possessing increased corrosion resistance. 316 stainless steel is often considered one of the most suitable choices when selecting austenitic stainless steel for marine applications. Other common applications of 316 stainless steel include Chemical processing and storage equipment. Refinery equipment Medical devices Marine environments, especially those with chlorides present.

Which Should You Use: Grade 304 or Grade 316?

Here are some situations where 304 stainless steel may be the better choice: The application requires excellent formability. The higher molybdenum content in Grade 316 can have adverse effects on formability. The application has cost concerns. Grade 304 is typically more affordable than Grade 316. Here are some situations where 316 stainless steel may be the better choice: The environment includes a high amount of corrosive elements. The material will be placed underwater or be exposed to water consistently. In applications where greater strength and hardness are required.

FAQ

Q: Are you a manufacturer or a trading company?

A: We are a factory, with 14 years’ selling experience.

Q: Where is your factory located?

A: Our factory is located in Wuxi city, in Jiangsu Province, China.

Q: How can I get a sample?

A: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q: What payment options do you offer?

A:Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;Accepted Payment Currency: USD, CNY;Accepted Payment Type: T/T,L/C,Credit Card,Western Union,Cash;

Q: What are the details of your after sales service?

A:1) We provide the necessary technical support to all of our customers, such as material performance and heat treatment data advice.

2) We provide the appropriate steel material technical parameters for customers in Germany, The USA, Japan, Britain, and other countries.